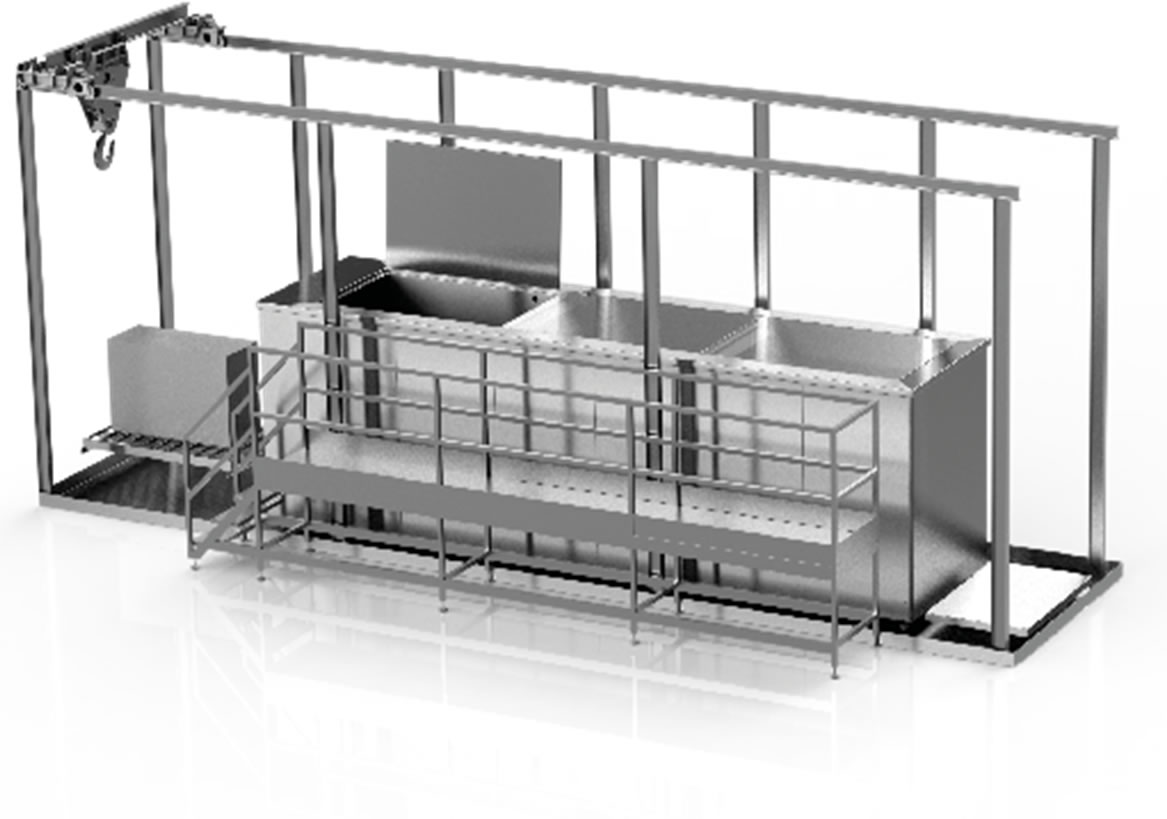

Multistage Ultrasonic Systems

BR-MOLD Series

- Multistage systems designed and manufactured exclusively for each client, meeting any cleaning and treatment needs

- Manual, semi-automatic or fully automatic equipment, with possibility to fully program all functions.

- Depending on the application and the parts to be treated, the stages of ultrasonic cleaning, rinsing, passivation, blowing, drying, etc. can be established.

- Sway function for better cleaning

- Pneumatic lifting up to 1000 Kg of load or hydraulic lifting from 1000 Kg

- Manual or automatic covers with the possibility of coating, thermo-acoustic insulation and pre-frame to prevent the escape of vapors

- Filtration systems for removing particles and pollutants from the wash tank

- OPS System: Exclusive process of eliminating oils, lubricants, greases and impurities by laminar sweeping and decanting for auxiliary tank

- Touch screen and PLC for monitoring and controlling the equipment. From this screen, the automation and programming of all equipment is controlled

Ultrasonic systems for

cleaning rubber molds

Ultrasonic systems for

cleaning plastic molds

BR-MAS Series

- 30-liter automatic equipment for small parts

- The AMS (Automatic Multi-Stage) line, includes multi-stage installations that carry out all processes in a fully automated way

- We provide the AMS equipment customized according to customers needs, which can be integrated into continuous production lines where human intervention is not required, or requiring an operator just to place and remove parts at the end of the process

- Optical, medical, pharmaceutical and industrial sectors

- 2 rinsing steps and a drying step with washing programs tailored to each client and touch screen control